CNC Clamping elements

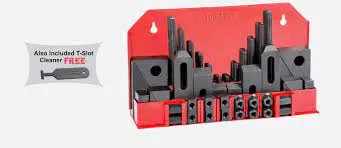

Clamping Kit with clamping elements

Clamping Kit with clamping elements

Secure and Adaptable: Clamping Elements for CNC Machines

CNC machining is all about precision, and clamping elements like T-bolts, T-nuts, and studs form the backbone of efficient workholding solutions. These foundational components ensure secure fastening, adaptability, and stability across diverse machining setups.

Types of Clamping Elements

- T-Bolts: Precision-machined for a snug fit in T-slots, ensuring stability under heavy loads.

- T-Nuts: Essential for creating secure connections, these nuts offer easy adjustability.

- Studs: Provide robust clamping force, ideal for high-pressure machining environments.

Benefits of Clamping Elements

- Secure Fastening: Eliminates workpiece movement, ensuring precise machining.

- Ease of Adjustment: Quick to reposition and adjust for different setups.

- Compatibility: Suitable for various machine tables and workpiece sizes.

Applications of Clamping Elements

- Fixture Assembly: For attaching jigs and fixtures securely to machine tables.

- Workpiece Clamping: Ensures stability during CNC operations like milling or drilling.

Partner with JAYPEE ASSOCIATES

Equip your machines with high-quality clamping elements from TOOLFAST, ARRIS, and ACCUFIX and more. Visit us online at https://jaypeeassociates.co.in/ to browse our collection and optimize your machining process.