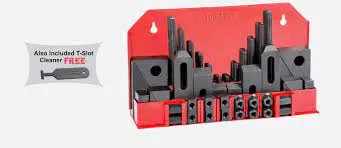

CNC Machine Toolings and Workholding fixtures

Clamping fixtures / Workholding.

Clamping fixtures / Workholding.

Unlocking Efficiency with CNC Clamping Fixtures and Workholding Tooling Solutions

In the fast-paced world of manufacturing, precision, speed, and reliability are paramount. CNC (Computer Numerical Control) machining, a cornerstone of modern manufacturing, requires robust support systems to maximize efficiency and output. Among these systems, clamping fixtures and workholding tooling solutions play a critical role.

What Are CNC Clamping Fixtures?

CNC clamping fixtures are specialized tools designed to hold a workpiece securely in place during machining. They ensure stability and precision, enabling the CNC machine to execute complex operations with minimal error. By eliminating movement and vibration, clamping fixtures enhance the accuracy and quality of the final product.

Key Benefits of Clamping Fixtures

- Enhanced Precision: Clamping fixtures ensure that the workpiece remains stationary, allowing for exact machining and intricate designs.

- Improved Safety: A securely held workpiece reduces the risk of accidents, protecting both the equipment and operators.

- Faster Setup Times: Well-designed fixtures reduce setup times, ensuring quicker transitions between operations.

- Consistent Quality: Fixtures allow for repeatability, producing identical results across multiple runs.

Exploring Workholding Tooling Solutions

Workholding tooling solutions encompass a range of devices, including vises, clamps, and chucks, tailored to meet diverse machining needs. These tools are essential for positioning and stabilizing workpieces, ensuring seamless integration with CNC machinery.

Types of Workholding Solutions

- Toggle Clamps: Ideal for quick and secure clamping, toggle clamps are widely used in repetitive operations.

- Modular Fixturing Systems: These versatile systems allow for easy customization to fit various workpieces.

- Pneumatic and Hydraulic Clamping: These advanced systems provide automated clamping for high-volume production.

- Magnetic Workholding: Suitable for ferrous materials, magnetic solutions offer quick setup and removal.

Importance in Modern Manufacturing

The right workholding tools are a game-changer for CNC machining. They not only streamline production but also:

- Reduce Downtime: By minimizing the need for frequent adjustments.

- Increase Productivity: By enabling higher machining speeds without compromising precision.

- Extend Tool Life: By ensuring proper alignment and reducing wear and tear on cutting tools.

Choosing the Right Solution

Selecting the appropriate clamping fixture or workholding tool depends on several factors, including:

- Type of CNC Operation: Milling, turning, or grinding.

- Material of the Workpiece: Aluminum, steel, or other materials.

- Size and Shape of the Workpiece: Complex shapes may require custom solutions.

- Volume of Production: High-volume operations often benefit from automated systems.

The Future of Workholding in CNC

With advancements in automation and smart manufacturing, workholding solutions are evolving. Modern fixtures integrate with CNC systems to provide real-time feedback, adjust clamping force, and ensure optimal performance. This trend towards intelligent workholding is paving the way for smarter, more efficient manufacturing.

Final Thoughts

Investing in high-quality CNC clamping fixtures and workholding tooling solutions is essential for manufacturers aiming to enhance efficiency and product quality. By ensuring stability and precision, these tools enable businesses to stay competitive in an ever-evolving market.

At JAYPEE ASSOCIATES, we are proud to be your trusted dealership for top-tier CNC tooling brands like TOOLFAST, ARRIS, and ACCUFIX and more. These industry-leading suppliers are renowned for their innovative and reliable products that cater to diverse manufacturing needs.

Discover how TOOLFAST’s clamping fixtures, ARRIS’s advanced tooling solutions, and ACCUFIX’s precision engineering can transform your machining operations. Visit our website at https://jaypeeassociates.co.in/ to explore our full range of products and learn more about how JAYPEE ASSOCIATES can support your business with world-class solutions. Or better yet, visit us at our office located on 31 Brabourne Road,3rd Floor, Kolkata – 700001.