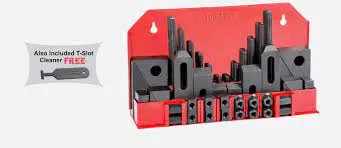

CNC Clamping Vise

A Clamping Vise

A Clamping Vise

Precision Redefined: CNC Clamping Vises

CNC machining demands tools that can hold workpieces with absolute reliability, and clamping vises are the cornerstone of this precision. Designed to stabilize materials during milling, drilling, or grinding operations, clamping vises enhance accuracy and operational efficiency in every machining process.

What Are CNC Clamping Vises?

Clamping vises are mechanical devices used to secure workpieces during machining. They are robust, versatile, and engineered to handle various material sizes and types, making them indispensable for CNC operations.

Benefits of Clamping Vises

- Unmatched Stability: Securely holds workpieces to prevent movement and vibration.

- Enhanced Accuracy: Ensures consistent alignment, leading to precise machining outcomes.

- Durability: Designed for heavy-duty use, clamping vises withstand high stress.

- Versatility: Adjustable designs accommodate a wide range of workpiece sizes.

Applications of Clamping Vises

- Milling Operations: Ensures workpieces stay fixed during high-speed cutting.

- Drilling Tasks: Provides stability for accurate hole placements.

- Grinding Jobs: Prevents shifts during surface finishing processes.

Why Choose JAYPEE ASSOCIATES?

At JAYPEE ASSOCIATES, we offer a curated selection of clamping vises from industry-leading brands like TOOLFAST, ARRIS, and ACCUFIX and more. Explore our range to find the perfect fit for your machining needs. Visit our website at https://jaypeeassociates.co.in/ to discover more.